horizontal centrifugal slurry pump

Latest articles

Settling slurries are formed from coarse particles; they are formed from unstable mixtures. It is these settling slurries with coarse particles.

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreThe discharge branch can be positioned at intervals of 45 degrees by request and oriented to any eight positions to suit installations and applications. There are many drive modes for option, such as V-belt, flexible coupling, gearbox, hydraulic coupler variable frequency, silicon controlled speed, etc. Among them, the flexible shaft coupling drive and V-belt feature of low cost and easy installation.

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreTypically, slurries are.

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreSlurry Pump

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreSites often rely on centrifugal pumps to provide slurry service. These pumps (and their associated piping systems) require special provisions that demand detailed knowledge of the properties of solids and slurries to prevent wear, corrosion, erosion and other adverse effects such as solids settling. Specifying the optimum combination of speed, geometry and material requires a proper balance of often conflicting pump priorities; this requires consideration of stable operation, maximum wear life, operational flexibility and minimum energy consumption.

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreSubmersible Slurry Pump

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreChoosing The Right Slurry Pump For Your Application

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreOn the other hand, if the slurry is not only abrasive but also has a low pH, then a duplex stainless steel construction is preferable. This material is best suited for slurry pumps to withstand harsh materials (such as acids) while still having a high Brinell hardness.

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreEspecially when the dredging depth reaches 20m or more, the above situation will be more obvious. The use of underwater pumps can effectively improve the above situation. The lower the installation position of underwater pumps, the smaller the suction resistance and vacuum, which can obviously reduce the losses during the work and improve the working efficiency. The installation of underwater pump can effectively increase the dredging depth and improve the ability to transport sediment.

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read MoreMud pumps are mainly used for drilling, pharmaceutical, brewing, paper, and other industries, which used to transport suspension.

horizontal centrifugal slurry pump...

horizontal centrifugal slurry pump 【horizontal centrifugal slurry pump】

Read More

Popular articles

- There is a better way to pump sewage, overflows and other collected dirty water around the plant.

- When dealing with slurry, you generally want to go bigger and slower. The thicker the impeller, the better it will hold up. The slower the pump, the less erosion will inflict on the impeller. However, the impeller isn’t the only thing to worry in slurry pump when dealing with slurry. Tough, durable materials of construction are necessary most of the time. Metal slurry pump liners and wear plates are common in slurry applications.

- Our firm has strong technical force and is specially engaged in the research of abrasion resistant materials of slurry pumps, sewage pumps and water pumps and the development of new products. The materials include high chrome white iron, duplex stainless steel, stainless steel, ductile iron, rubber, etc.

- Slurry Pump

- Slurry pumps can also simply axially adjust the clearance between the impeller and the adjacent throat casing sealing surface. This helps to maintain pump performance when internal components begin to wear.

- AIER will always strive to be your common sense slurry pump and parts supplier in a complex world!

Latest articles

-

Carbon transfer

-

>Slurry Pump VS Mud Pump

-

In harsh conditions with sand, sludge, rocks and mud, ordinary slurry pumps tend to clog, wear and fail frequently. But WA heavy duty slurry pumps are highly resistant to wear and corrosion, which means that the service life of our slurry pumps is better than other manufacturers' pumps.

-

Slurry Pump

-

Slurry pump power adjustment

-

How much solids damage can the customer tolerate?

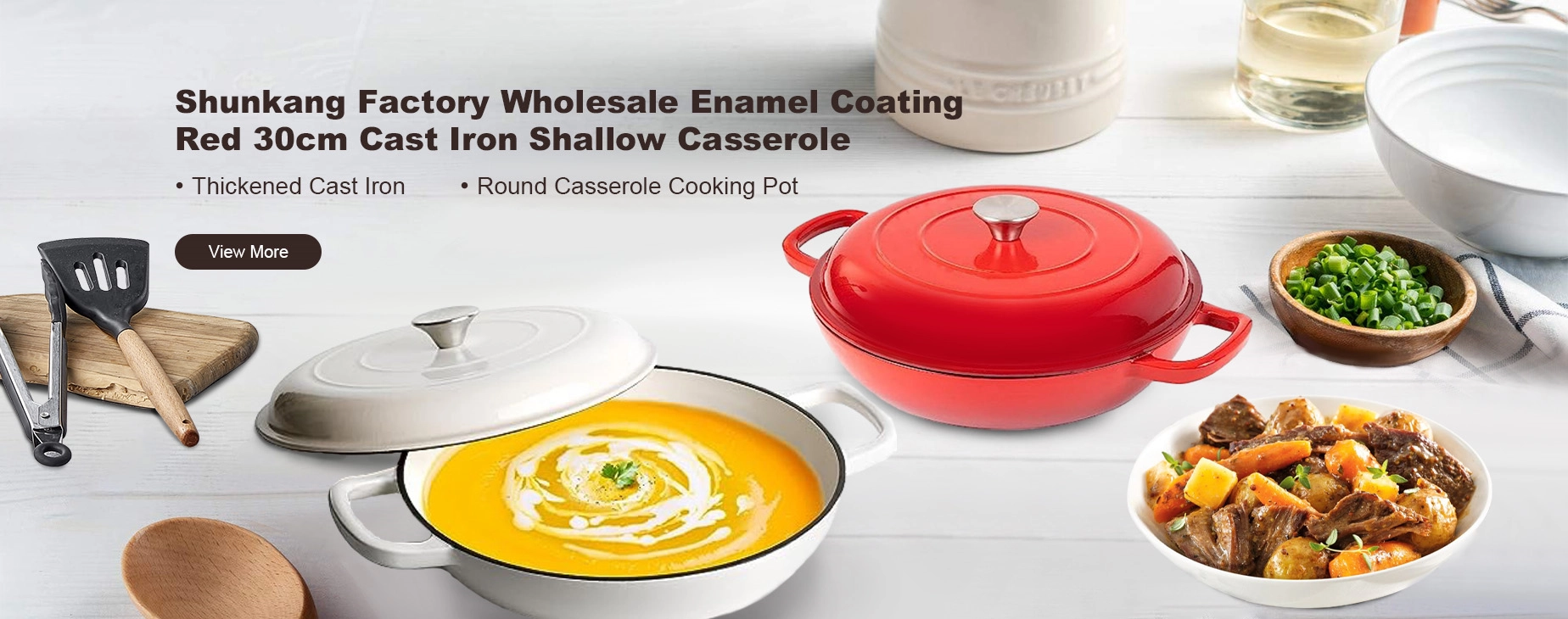

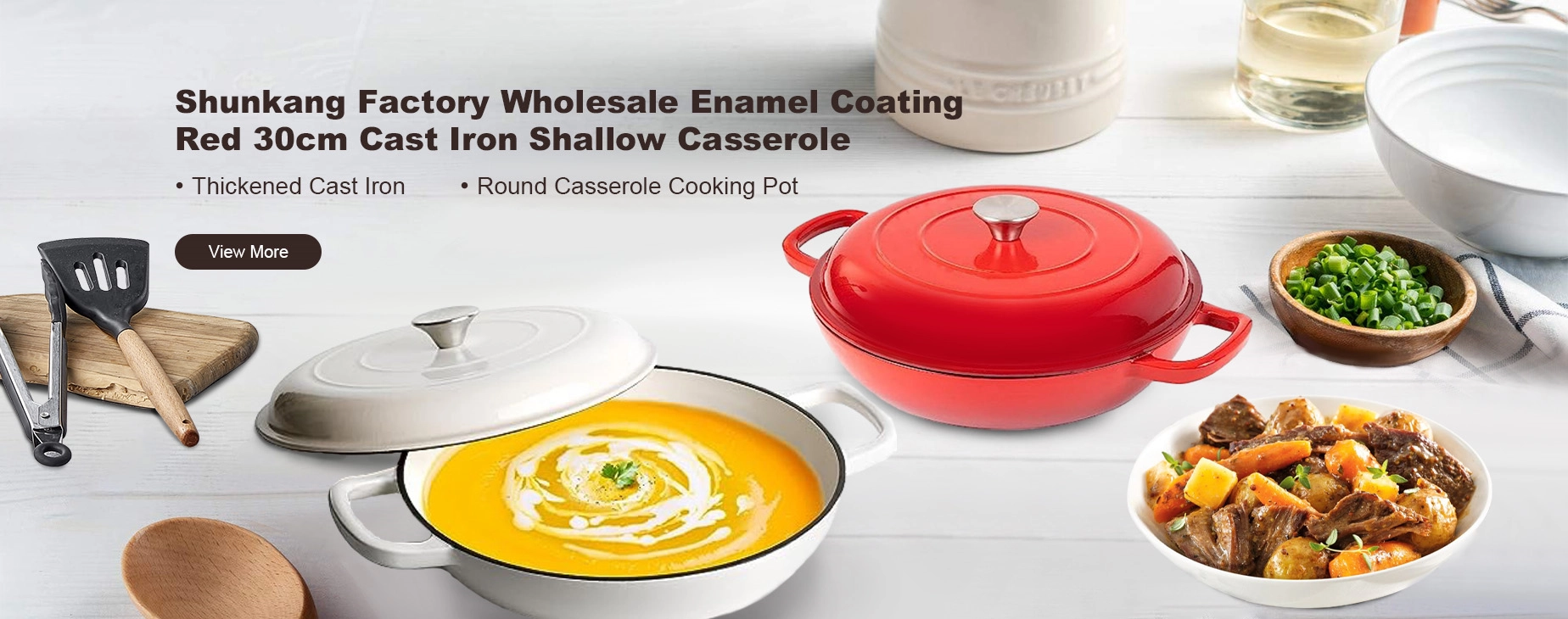

Commercial cast iron griddles

Electric stoves often have hotter areas around the center of the burner Electric stoves often have hotter areas around the center of the burner

Electric stoves often have hotter areas around the center of the burner Electric stoves often have hotter areas around the center of the burner using cast iron griddle on electric stove. You might need to rotate your griddle or shift it slightly to ensure even cooking. Also, consider that the heat will persist under and around the griddle longer than on a gas stove, so adjusting the temperature earlier than you would on a gas stove is advisable when you approach the end of cooking.

using cast iron griddle on electric stove. You might need to rotate your griddle or shift it slightly to ensure even cooking. Also, consider that the heat will persist under and around the griddle longer than on a gas stove, so adjusting the temperature earlier than you would on a gas stove is advisable when you approach the end of cooking.When it comes to maintenance, cast iron double griddles require minimal effort. Regular seasoning and proper cleaning will keep your cookware in tip-top shape. With its sturdy construction and low maintenance, cast iron double griddles are undoubtedly a favorite among home cooks and professional chefs alike.

Cast Iron Dutch Oven Cooking

Benefits of Enamel Cookware:

Skillets are typically deeper than frypans, which makes them more suitable for dishes that call for more liquid or sauce. Its depth also allows you to add in more ingredients for one-pan meals that include vegetables and meat. All this without spilling out.

With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions

With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions With proper care, these griddles can last for generations, becoming cherished heirlooms that carry on family culinary traditions griddle grill cast iron.

griddle grill cast iron. Their heat retention capabilities also mean they keep food warm for longer periods after cooking Their heat retention capabilities also mean they keep food warm for longer periods after cooking

Their heat retention capabilities also mean they keep food warm for longer periods after cooking Their heat retention capabilities also mean they keep food warm for longer periods after cooking porcelain coated cast iron cookware sets.

porcelain coated cast iron cookware sets. A solid collection might include a spatula, ladle, tongs, wooden spoons, and a whisk A solid collection might include a spatula, ladle, tongs, wooden spoons, and a whisk

A solid collection might include a spatula, ladle, tongs, wooden spoons, and a whisk A solid collection might include a spatula, ladle, tongs, wooden spoons, and a whisk cooking set for kitchen. Opt for heat-resistant materials that won't scratch your cookware.

cooking set for kitchen. Opt for heat-resistant materials that won't scratch your cookware.

Dutch ovens, on the other hand, are known for their versatility. Dutch ovens can be used for everything from soups and stews to toast and roasts.

Advantages:

This adaptability extends the scope of your outdoor cooking, letting you enjoy the sizzle and smoky flavors of the grill in any setting This adaptability extends the scope of your outdoor cooking, letting you enjoy the sizzle and smoky flavors of the grill in any setting

This adaptability extends the scope of your outdoor cooking, letting you enjoy the sizzle and smoky flavors of the grill in any setting This adaptability extends the scope of your outdoor cooking, letting you enjoy the sizzle and smoky flavors of the grill in any setting grill guru cast iron sizzling plate.

grill guru cast iron sizzling plate.

Overall, knowing how to repair broken enamel cookware can help you extend the life of your favorite pots and pans. Whether it's ceramic and enameled cast iron cookware or enamel-coated cast iron cookware, there are options for repairing broken enamel and restoring your cookware to its former glory. By promptly treating enamel chips and using safe and effective repair methods, you can continue to enjoy the benefits of enamel cookware for years to come.